Quality assurance

We ensure that the quality is top-notch

Our quality management system ensures that our customers’ wishes are met. This is done by specific instructions that are prepared upon confirmation of the individual order. The management system detects errors in such a way that experience is built up so that similar errors are avoided in the future. The experience gained is also used to continuously improve production methods.

This is why our quality is top-notch

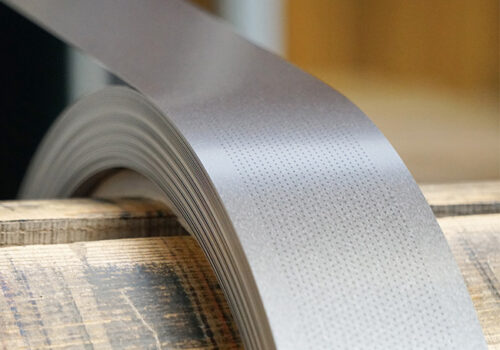

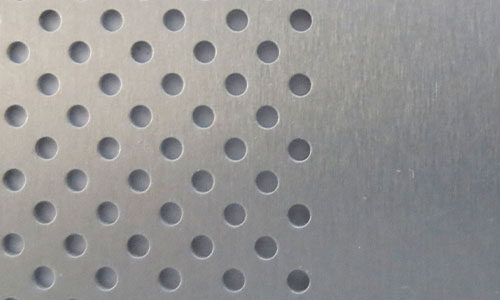

A nice cut

It does not take much before a perforated surface looks completely wrong. Even the smallest burrs, discolorations in the hole itself as well as the geometry around the entrance hole have an influence on how the result will be. Therefore, we have installed a lot of light around our production lines so that even the smallest variations are detected in time.

It is mistaken to think that making a hole is a simple task. Yes, making one hole is quite easy. But when 100-thousands come right after one another and often quite close to each other, then it starts to get difficult. That is why we rely very much on the feedback we receive from our customers. We are therefore also particularly proud that many of our customers have been our regular partners for decades.

A clean working environment

It is crucial that production takes place in a clean environment. Dust and other volatile particles must not come close to our production. We work quite often with very delicate surfaces, where even the smallest particles can give scratches on the material. Cleaning the machine lines, as well as washing the floors in our production, is part of our regular routine.

Quality control

Our skilled staff regularly inspects the ongoing perforation process for each individual task. Thereby we ensure that any production errors are found and stopped quickly. As a result, we have minimal production waste and customers receive the largest amount of usable coils in return. When the perforation process is completed, we check the product once again and ensure that the quality is top-notch.

References

Metalcolor – Schweiz

For many years Metalcolor SA and Dan-How Perforation ApS have been collaborating.

For Metalcolor, Dan-How is a very reliable partner and in our opinion the best in the field.

Customers are delivered with Swiss quality pre-painted aluminium coils in an infinite range

of colours, coated by Metalcolor, with precise micro-perforation performed by Dan-How.

Servis Climax a.s. – Tjekkiet

Climax is working with Dan-How Perforation already for ages and all the time we are more

than happy to have such a reliable supplier. It is always important to have precise deliveries

in means of quality and time and Dan-How is matching those needs perfectly

Metalpaint AG - Schweiz

We appreciate your support and your collaboration with Metal Paint

and we are convinced they will be a good relationship.

HAUFE-Deckensysteme GmbH-Tyskland

Als Hersteller von Deckensystemen arbeiten wir seit gut 10 Jahren mit der Firma Dan-How eng zusammen,

die für uns die Bänder unserer Lamellendecken mikroperforiert. Um die Qualität unserer Systeme auf einem

gleichbleibenden hohen Niveau zu halten ist es für uns wichtig, dass der vereinbarte Qualitätsanspruch an

Lochung und Richtqualität verbindlich eingehalten wird. Ebenso müssen wir durch die Objektarbeit Liefertermine

verbindlich einhalten und oft auch sehr kurzfristige Lieferungen realisieren. Die Firma Dan How hat uns hier immer

voll unterstützt und stehts pünktlich die geforderte Qualität geliefert. Wir schätzen diese Zuverlässigkeit und die

immer freundliche Zusammenarbeit, auf die wir hoffentlich auch zukünftig setzen können. Herzlichen Dank

vom gesamten Team der HAUFE Deckensysteme GmbH.

Svenska Westaflex AB - Sverige

I snart 10 år har vi skickat vårt material för perforering till Dan-How Perforation, och vi är

väldigt nöjda att ha dom som leverantör. Kompetenta och väldigt trevliga. Rekommenderas starkt.